Lallemand Brewing Belgian Wit-Style Ale Yeast Winequip

$ 6,29 $ 3,77

LalBrew® Wit yeast is a relatively neutral strain which can be used to produce a wide variety of wheat beer styles. Ester and phenol production is lower than for traditional hefeweizen strains such as Munich Classic. LalBrew® Wit provides a baseline profile of banana and spice aromas, but leaves space for the brewer to showcase other spice additions typical of Belgian style beers. Traditional styles brewed with this yeast include but are not limited to Belgian Witbier, American Wheat, Berliner Weiss, Gose, Hefeweizen, Dunkelweis, and Weizenbock.

Pack Sizes:

- 11g Sachet

Beer Styles:

- Wheat Beers

- Belgian Witbier

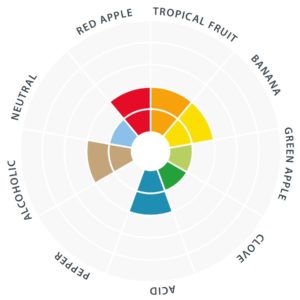

Aroma:

- fruity, slight banana and clove

Attenuation:

- medium to high

Fermentation Range:

- 17 – 22°C (63 – 72°F)

Flocculation:

- low

Alcohol Tolerance:

- 12% ABV

Pitching Rate:

- 50 – 100g/hL to achieve a

- minimum of 2.5 – 5 million cells/mL

MICROBIOLOGICAL PROPERTIES:

Classified as a Saccharomyces cerevisiae, a top fermenting yeast.

Typical Analysis of LalBrew® Wit Yeast:

Percent solids 93% – 97%

Living Yeast Cells ≥ 5 x 109 per gram of dry yeast

Wild Yeast < 1 per 106 yeast cells

Bacteria < 1 per 106 yeast cells

Finished product is released to the market only after passing a rigorous series of tests

*According to the ASBC and EBC methods of analysis

BREWING PROPERTIES

In Lallemand Standard Conditions Wort at 20°C (68°F) LalBrew® Wit yeast exhibits:

Vigorous fermentation that can be completed in 4 days

Medium to High attenuation and Low flocculation

Aroma and flavor is somewhat estery with banana notes

The optimal temperature range for LalBrew® Wit yeast when producing traditional styles is 17°C(63°F) to

22°C(72°F)

Fermentation rate, fermentation time and degree of attenuation are dependent on inoculation density, yeast handling, fermentation temperature and nutritional quality of the wort.

Flavour and Aroma:

Instructions for use:

The pitch rate will affect the fermentation performance and flavor of the beer. For Wit yeast, a pitch rate of 50 – 100g per hL of wort is sufficient to achieve optimal results for most fermentations. More stressful fermentations such as high gravity, high adjunct or high acidity may require higher pitch rates and additional nutrients to ensure a healthy fermentation.

Find your exact recommended pitching rate with our Pitch Rate Calculator in our Brewers Corner at

Wit may be re-pitched just as you would any other type of yeast according to your brewery’s SOP for yeast handling. Wort aeration is required when re-pitching dry yeast.

Rehydration:

Rehydration of Wit in sterile water is recommended prior to pitching into wort in order to reduce stress on the cell as it transitions from dry to liquid form. For many fermentations, this stress is not significant enough to affect fermentation performance and flavor, so good results may also be achieved when pitching dry yeast directly into wort. We highly recommend rehydration in harsher fermentation conditions such as high gravity or sour wort where the added stress of dry-pitching is more likely to have a greater impact on the finished beer. Use of a rehydration nutrient such as Go-Ferm Protect Evolution has been shown to improve fermentation performance for difficult fermentations. Rehydration guidelines are quite simple and present a much lower risk of contamination than a starter, which is unnecessary when using the recommended pitch rate of dried active yeast. Sprinkle the yeast on the surface of 10 times its weight in clean, sterilized water at 30-35°C (86-95F). Do not use wort, or distilled or reverse osmosis water, as loss in viability may result. Stir gently, leave undisturbed for 15 minutes, then stir to suspend yeast completely. Leave it to rest for 5 more minutes at 30-35°C. Without delay, adjust the temperature to that of the wort by mixing aliquots of wort with the rehydrated yeast. Wort should be added in 5 minute intervals and taking care not to lower the temperature by more than 10°C at a time. Temperature shock of >10°C will cause formation of petite mutants leading to extended or incomplete fermentation and possible formation of undesirable flavors. Do not allow attemperation to be carried out by natural heat loss. This will take too long and could result in loss of viability or vitality. Inoculate without delay into cooled wort in the fermenter. Wit yeast has been conditioned to survive rehydration. The yeast contains an adequate reserve of carbohydrates and unsaturated fatty acids to achieve active growth. It is unnecessary to aerate wort upon first use.

Packaging & Storage:

Wit yeast should be stored in a vacuum sealed package in dry conditions below 4C° (39°F). Wit will rapidly lose activity after exposure to air. Do not use 500g or 11g packs that have lost vacuum. Opened packs must be re-sealed, stored in dry conditions below 4°C (39°F), and used within 3 days. If the opened package is re-sealed under vacuum immediately after opening, yeast can be stored below 4C° (39°F) until the indicated expiry date. Do not use yeast after expiry date printed on the pack. Performance is guaranteed when stored correctly and before the expiry date. However, Lallemand dry brewing yeast is very robust and some strains can tolerate brief periods under sub-optimal conditions. If you have questions, do not hesitate to contact us.

Fast Shipping with Professional Packaging

We provide a variety of shipping options thanks to our long-standing relationships with UPS, FedEx and DHL. Our warehouse personnel are well trained and will be able to pack your goods in accordance with the exact and precise specifications. Before shipping, all goods are carefully examined and secured. We deliver to thousands of clients each day across multiple countries. The fact that we're dedicated to becoming the largest online retailer in the world is obvious. Warehouses and distribution centers can be found in Europe as well as the USA.

Orders that contain more than one item are assigned processing times according to each item.

We will inspect each and every one of the items ordered before shipping. The majority of orders are shipped within 48-hours. Delivery is expected to take between 3 and seven days.

Returns

We do not manage the stock in our warehouse or factory. The levels of stock can change at any time. Please be aware that it's possible for your order to be out of stock after you have placed the order.

The policy is 30 days. If it's been longer than 30 days since you bought the item We're sorry to say that we can't offer you a full refund or exchange.

The item cannot be used, and it must be in its original condition. It must also still be in the original package.

Related products

Equipment

Equipment

Equipment

Brewing Aids

Brewing Aids

Equipment

Equipment

Equipment