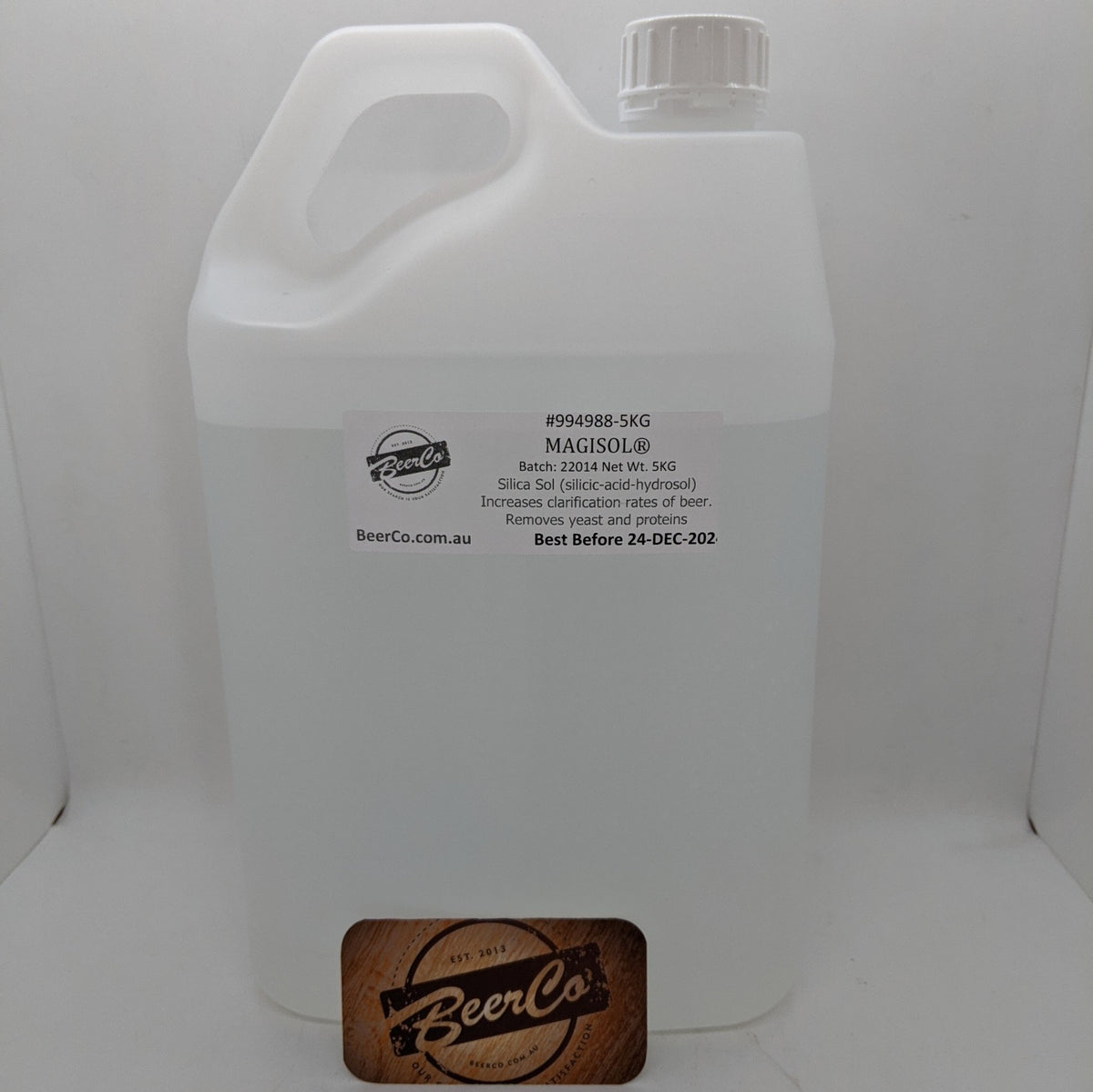

MagiSol® 300 | Silica Sol Zymus

$ 34,95 $ 20,97

MagiSol® 300 | Silica Sol (silicic-acid-hydrosol) is a colloidal solution of silicic acid (SiO2) in water. It appears bluish opalescent and consists of special unlinked particles of amorphous silicic acid. The surface of the particles is hydroxylised; the particles possess no internal porosity and are negatively charged. For this reason, Silica Sol is resistant to agglomeration and precipitation.

Benefits

- Increases clarification rates of beer

- Removes proteinaceous material as well as yeast

- Can be used at hot wort stage and at maturation

- Meets the requirements of the Reinheitsgebot, the German Purity Law for brewing

Packaging

MagiSol® 300 is packed in the following sizes:

- 1 Kg HDPE Bottles

- 5 Kg HDEP Bottles (SAVE 20% OFF 1Kg Price)

- 70 Kg Drums (SAVE 32% OFF 1Kg Price)

- 1250 Kgs / IBC (available upon request / preorder from [email protected] )

Characteristics

Density: 1.2 g/mL

Internal Surface Area: 300 m²/g SiO2

Particle Size Distribution: 5 – 140 nm

Applications

Hot Cast Wort: The easiest way to use MagiSol® 300 is in the treatment of the hot cast wort. MagiSol® 300 is applied in the copper after boiling or dosed into the wort stream before the whirlpool. The precipitate settles with the hot break.

It is not advised to boil MagiSol® 300 with the wort in an attempt to get an intensive distribution, as the silicic acid flocculation will be broken up, therefore making it difficult to separate.

The hot break can still be blended with the spent grains if this is the practice, as the amount of SiO2 is negligible in relation to the dry matter of the spent grains.

Maturation: Also the addition of MagiSol®300 is routinely used in fermented beer at the transfer process. Stabisol 300 will have greatest effect if the fermentation is complete and the temperature is close to the freezing-point. The bulk of the haze-forming components are already insoluble, and together with other filtration impeding substances; they are absorbed by the silica sol and settle to the tank bottom. With this addition, a fast clarification is achieved, and this also leads to an optimisation of filtration.

Dosage Guidelines

It is not possible to give exact advice on the dose rate of MagiSol® 300 without preliminary tests, but some initial guidelines or starting points are given:

Hot Cast Wort: Customarily, addition rates of between 30 mL and 60 mL MagiSol® 300 per hectolitre of cast wort. At a density of 1.2, this is equivalent to 36 and 72 g/hL or 11 and 22 g SiO2.

Maturation: Commonly, 50 mL of Stabisol 300 per hectolitre of beer at 0°C is an initial starting point for determining optimum dose rates at the transfer process, but also see below.

Optimisation: At 0°C, increasing quantities of Stabisol 300 from 20, 25 to 45, 50 mL/hL should be added to the beer, after precipitation and removal of the precipitate the beer should be tested for filterability.

Storage

MagiSol® 300 is sensitive to chilling and should be stored at ambient temperatures above 0°C (at or below freezing point it converts to water-insoluble silica gel). The material can be held in stock for 18 months, if stored properly.

Safety and Enzyme Handling

Inhalation of dust and mists should be avoided. In case of contact with the skin or eyes, promptly rinse with water for at least 15 minutes.

For detailed handling information, please refer to the Material Safety Data Sheet.

Manufactured in New Zealand for BeerCo.au

| Size | 1 Kg, 5 Kg, 70 Kg |

|---|

Fast Shipping with Professional Packaging

We provide a variety of shipping options thanks to our long-standing relationships with UPS, FedEx and DHL. Our warehouse personnel are well trained and will be able to pack your goods in accordance with the exact and precise specifications. Before shipping, all goods are carefully examined and secured. We deliver to thousands of clients each day across multiple countries. The fact that we're dedicated to becoming the largest online retailer in the world is obvious. Warehouses and distribution centers can be found in Europe as well as the USA.

Orders that contain more than one item are assigned processing times according to each item.

We will inspect each and every one of the items ordered before shipping. The majority of orders are shipped within 48-hours. Delivery is expected to take between 3 and seven days.

Returns

We do not manage the stock in our warehouse or factory. The levels of stock can change at any time. Please be aware that it's possible for your order to be out of stock after you have placed the order.

The policy is 30 days. If it's been longer than 30 days since you bought the item We're sorry to say that we can't offer you a full refund or exchange.

The item cannot be used, and it must be in its original condition. It must also still be in the original package.

Related products

Brewing Aids

Equipment

Brewing Aids

Brewing Aids

Equipment

Equipment

Adjuncts

Brewing Aids

Equipment

Equipment

Equipment

Equipment

Brewing Aids